Brake dust filter hood with vortex generator and final separator

The innovative system can detach the boundary layer near the brake disc (which is loaded with brake dust particles) very efficiently and direct it into the filter mats. Overall, the amount of particulate matter released into the environment is significantly reduced.

Challenge

About 85% of the traffic-related particulate matter is formed by tire, brake and road abrasion as well as by the whirling up of the dust layer on the roadways. Brake dust is classified as hazardous to health and is particularly dangerous in the air we breathe. Brake dust particles can (depending on their size) penetrate relatively deep into the lung tissue and partly into the bloodstream. Due to the nature of brake discs and pads, the brake dust particles can contain extremely harmful substances (e.g. nickel, chromium and copper). Currently available, active systems for collecting brake dust usually worsen the energy balance of the vehicle. Passive solution concepts cannot efficiently break the boundary layer near the brake disc and cannot efficiently collect the brake dust. The enclosure increases the thermal load on the brake disc, which is detrimental to durability and safety.

Our solution

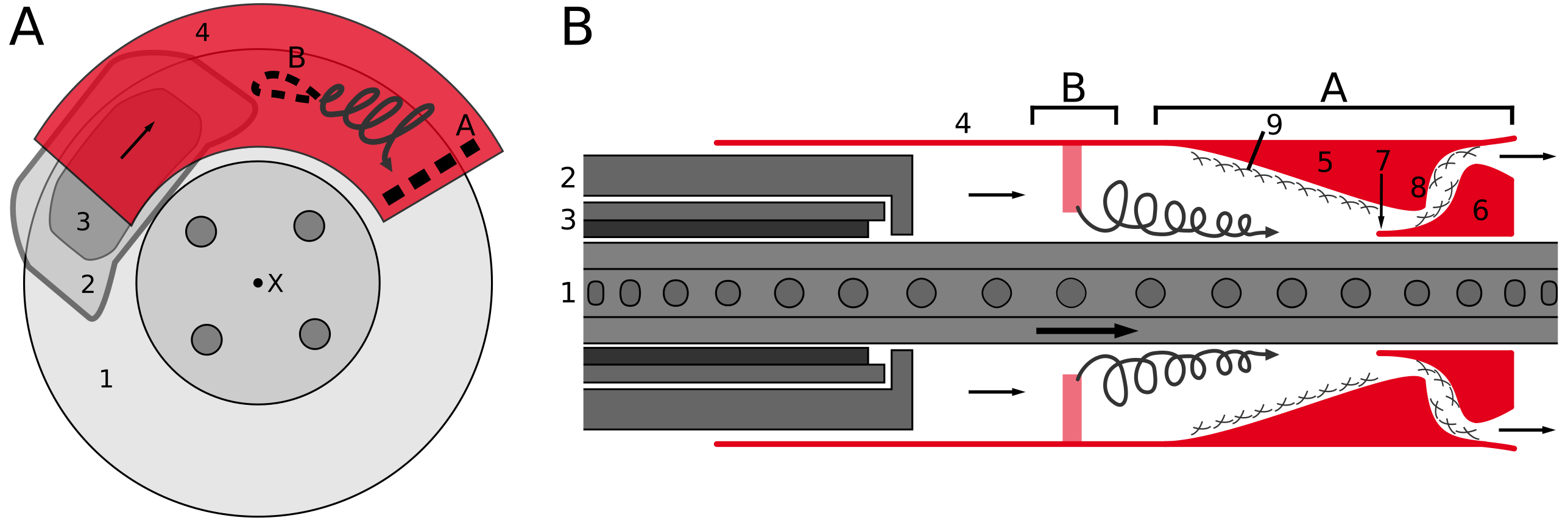

Prof. Klinge from the Ostfalia University of Applied Sciences has developed a filter hood that has filter mats inside and includes a special flow guide that enables extremely efficient detachment of the boundary layer loaded with dust particles from the brake disc. With air deflectors, the flow cross-section inside the hood is first reduced. With the help of an end separator and subsequent deflection of the flow, the boundary layer is detached from the brake disc. The cutting edge also supports the sealing of the filter hood, while the changing pressure conditions in the hood favor the separation of the brake dust particles in filter mats.

Figure 1: Schematic representation of the brake dust filter system according to the invention with final separator A and vortex generator B. 1 – brake disc, 2 – brake caliper, 3 – brake pad, 4 – filter hood, 5 – air deflector, 6 and 8 – flow deflection, 7 – cutting edge, 9 – filter mat (source: adaptation after patent application).

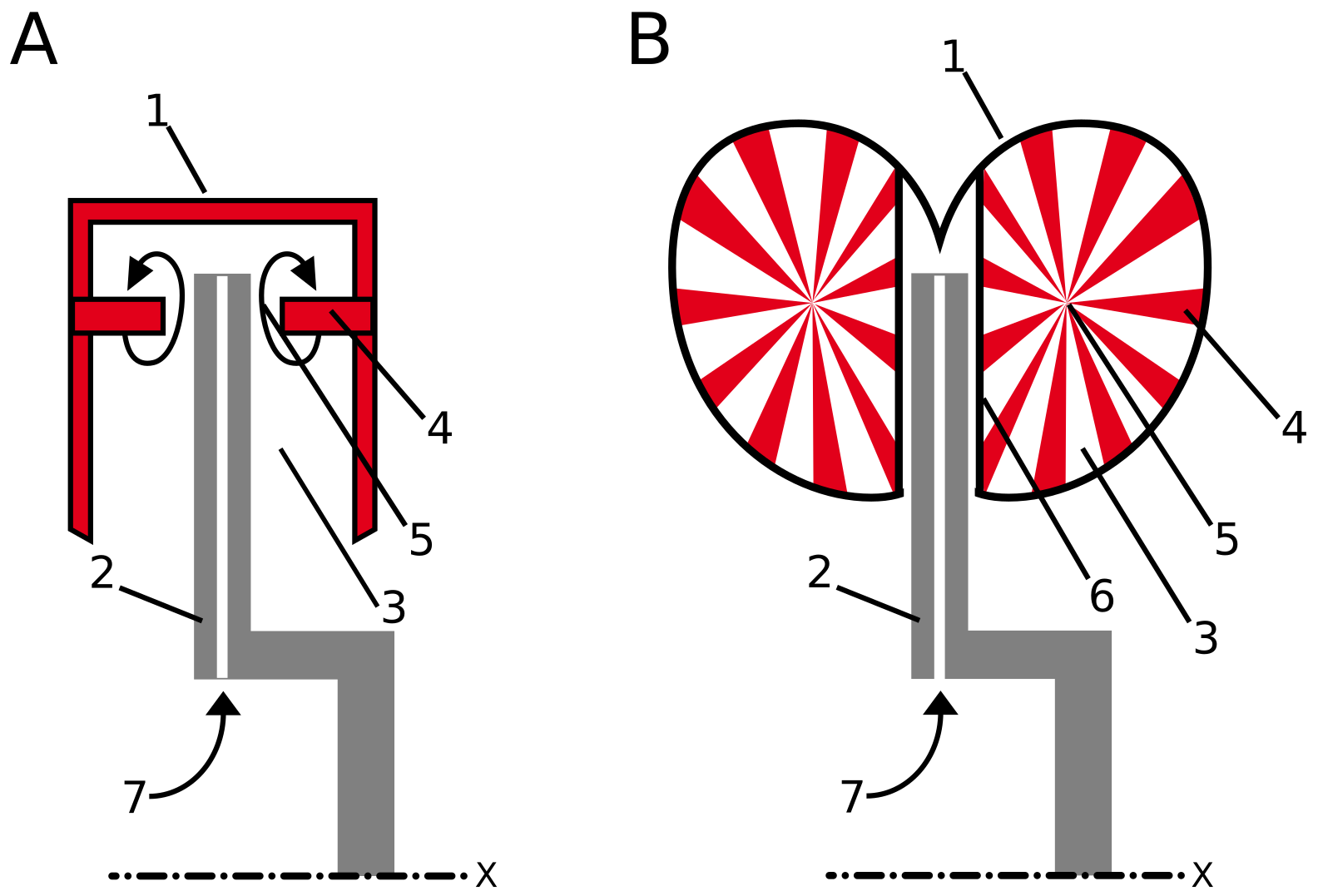

An optionally integrated vortex generator favors the detachment of the boundary layer. In addition, the vortex generator can already provide an advantage in a simpler filter hood even without the final separator. In a particularly advantageous design, the filter hood has a pretzel shape in cross-section, wherein the vortex generator is designed in the form of a impeller. This can create a particularly stable vortex in the filter hood. This also supports the flow through the ventilation ducts of the internally ventilated brake disc and thus reduces the thermal load on the brake disc.

Figure 2: Possible embodiments of the filter hood according to the invention with vortex generator. 1 – Filter hood, 2 – Brake disc, 3 – Flow channel, 4 – Wing-shaped vortex generator, 5 – Air vortex, 6 – Air conduction element, 7 – Internal ventilation (Source: Adaptation after patent application).

Advantages

- Increased precipitation of brake dust compared to conventional passive filter hoods

- Efficient removal of the boundary layer from the disc brake without negative influence on the brake cooling

- Effective seal without contact to moving parts

- No additional energy consumption (passive operating principle)

- Retrofit option given

Applications

- Cars, trucks and two-wheelers (regardless of the type of drive)

- Rail vehicles

Development Status

First prototypeshave been developed and tested in the wind tunnel.

Patentsituation

German patent application:

DE102020105241A1

DE102020105240B4

Patent holder:

Ostfalia University of Applied Sciences – Hochschule Braunschweig/Wolfenbüttel

Related Technologies

Brake dust collector with venturi suction generator for active boundary layer manipulation

Contact

Dr. Mirza Mackovic

Patent Manager Technology

E-Mail: mmackovic(at)sciencebridge.de

Phone: +49 (0) 551 30 724 153

References: MM-2244-FHBW and MM-2245-FHBW

www.sciencebridge.de

Tags: Automotive engineering