Increasing the reactivity of Isocyanate binders

An improved process for the production of wood-based panels based on isocyanate binders / adhesives (PMDI) was developed at the University of Göttingen. The times and costs for production of wood-based materials (e.g. chipboard, fiberboards (MDF, HDF), OSB etc.) can be reduced without neccessity to change hardware in existing production lines or plants.

Challenge (in h2)

An alternative to condensation resins such as urea-formaldehyde (UF), melamine-urea-formaldehyde (MUF) and phenol-formaldehyde (PF), also isocyanate binders (PMDI) are used to glue cellulose based materials. The advantages of PMDI are a good wetting behavior of wooden surfaces and a good penetration into the wood compared to aqueous amino- or phenol-based condensation resins. Another advantage of isocyanate binders over formaldehyde resins is that they have no formaldehyde emission. Furthermore, they are resistant to moisture, which means that the use of paraffins can be reduced and the products can be used both outdoors and in wet rooms. A major disadvantage of isocyanate binders, however, is their relatively low reactivity, which leads to a significantly longer times for pressing and thus higher costs. Even though the better wetting behavior of isocyanate based binders allows a reduction of the amount of the binder, their use is still more expensive compared to most formaldehyde based condensation resins.

Our Solution (in h2)

The inventors identified inexpensive and non-toxic ammonium salts that were until now not used together with isocyanate binders. The salts enable the production of wood-based materials such as chipboard and fiberboard to be accelerated. The maximum strength could be achieved with a significantly reduced pressing time. This is an economic advantage, since more panels can be produced in the same time without major investments in new production lines. In addition to the increase in reactivity, there is also an improved crosslinking during the reaction. This should lead to increased stability of the wood-based material and to advantages in terms of resistance to washing out the binder.

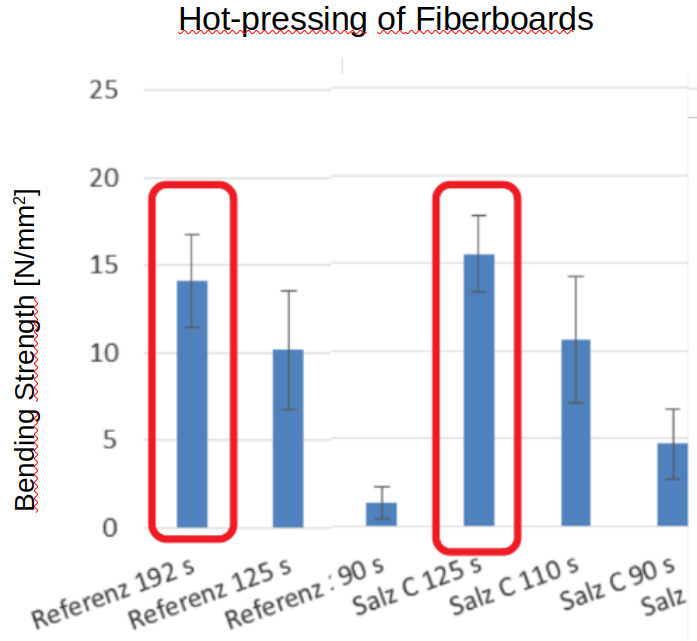

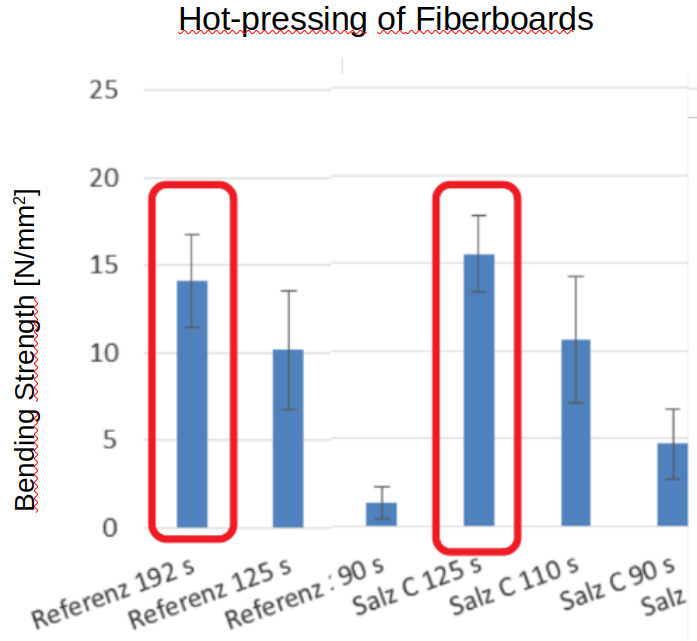

Figure 1: Influence of an accelerator salt on bending strength of chipboards pressed at the same temperature. The maximum board strength was achieved with a reduction of the pressing time by 35%.

Figure 1: Influence of an accelerator salt on bending strength of chipboards pressed at the same temperature. The maximum board strength was achieved with a reduction of the pressing time by 35%.

A significantly stronger acceleration was achieved when glueing micro-veneers. In this case, the time could be shortened by a factor of ten, while simultanously lowering the temperature.

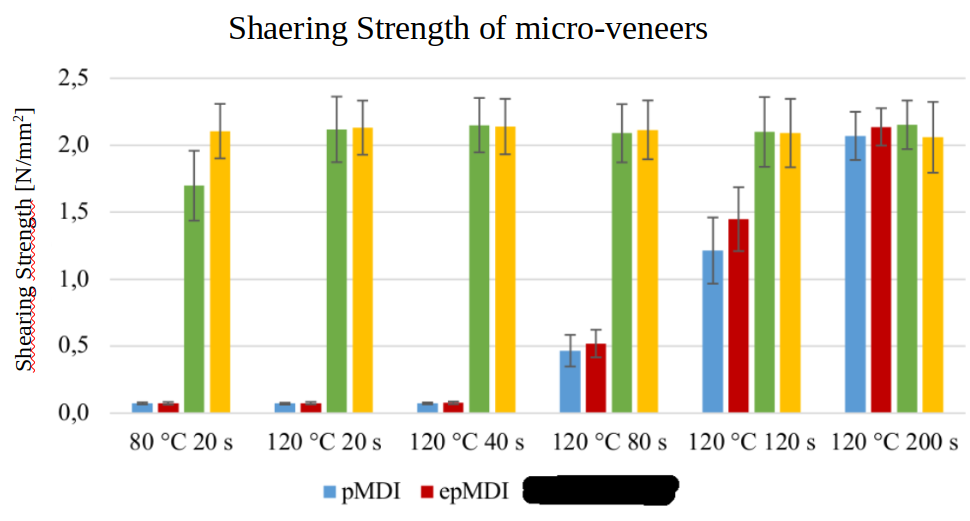

Figure 2: Shaering Strength of glued micro-veneers. By adding the accelerator salts (green and yellow bars) the isocyanate hardens faster and at a lower temperature.

Figure 2: Shaering Strength of glued micro-veneers. By adding the accelerator salts (green and yellow bars) the isocyanate hardens faster and at a lower temperature.

Surprisingly, the increased reactivity does not decrease the time in which the Binder can be used (pot life). In contrast, the pot life is prolonged at 25°C. At the same time, the addition of the salts result in a decreased gel-time. Thus not only the overall process is significantly faster, also the whole process from preparing the binder until the crosslinking finished is simplified significantly!

Advantages (in h2)

- significantly accelerated hardening of isocyanate binders

- increased pot-life at 25°C and decreased geling time at elevated temperatures simplify the whole production process

- Lower temperatures and/or shorter pressing times are possible 2

- Use of lower amount of binder should be possible

- Reduced production costs

- Increase in the production capacity by approx. 35% in exisiting production lines

- The reaction does not lead to a linear, but to a 3D cross-linking, which should lead to increased mechanical stability and an improved resistance to washing out

Development Status (in h2)

The acceleration of the isocyanate cross-linking is proven with different materials and temperatures in a laboratory scale.

Patent Status (in h2)

We have a pending European patet appication. Exclusive and Non-Exclusive licenses are possible

Contact

Dr. Martin Andresen

Patent Manager Life Sciences

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +49 551 30724 150

Reference: BioT-2257-SUG

Tags: reactivity, Adhesive, PMDI, isocyanate, binder, USB, OSB, HDF, MDF, Wood