Production of three-dimensional moldings from popcorn using innovative molding technology

The present invention relates to moldings made from popcorn, which has been hydrophobicized with a polymer. This allows for production of very light, flexible and water-repellent moldings. In particular, the moldings consist of renewable raw materials. Applications are e.g. for packaging and consumer goods industry.

Challenge

Today, molded parts (from polymers) like packaging materials are mainly made of polypropylene, polyethylene, polyvinyl chloride and polystyrene. Although they have positive properties such as low density, hydrophobic surfaces, good processability and low thermal conductivity, they also have numerous negative properties. For example, the material is often brittle, has very low chemical resistance and a very low melting temperature. In addition, these plastics are made from finite fossil raw materials, some of which are difficult to reuse. The increase of plastic waste on land and especially in the oceans is becoming an ever greater ecological problem of global significance. Due to these problems, alternative solutions are urgently needed.

Our Solution

Scientists at the Georg-August-University of Göttingen, Germany developed molded parts consisting of popcorn (expanded kernels) and a new molding press process.

The granulated popcorn used for the production of the three-dimensional moldings is coated with a polymer before molding. Due to this coating the popcorn can be stored very well as a pourable granulate before further processing. The new production process uses radio wave technology and is therefore faster and more efficient, thus more cost-effective. The molded parts produced have improved good to excellent properties, such as improved pliability and water-repellent (hydrophobic) properties. In particular, they can be made predominantly from renewable raw materials.

The two techniques, compression molding and automatic molding have been further developed to produce the inventive molded parts. Depending on the application, the surface of the molded parts can then be coated or laminated.

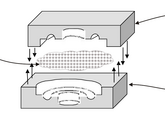

Compression molding (Fig. 1):

The popcorn surrounded by polymer is placed in a cavity which is heated under pressure and conductive heat transfer. The pressure gives the molding compound the shape specified by the mold.

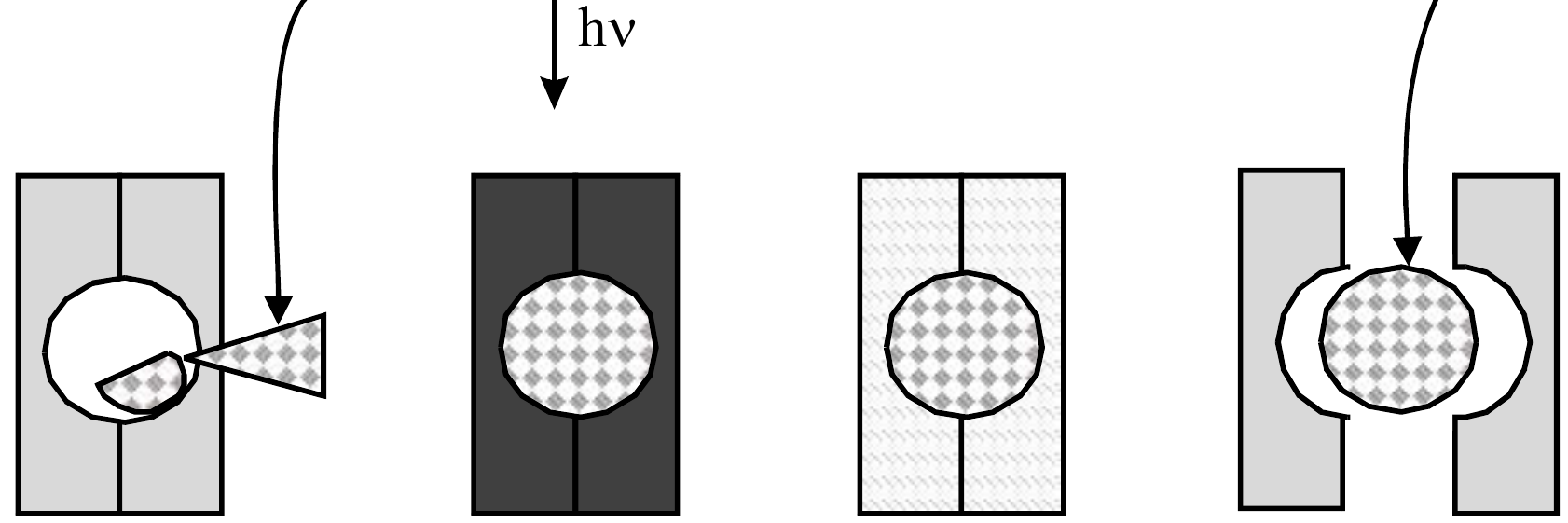

Use of automatic molding machines (Fig. 2):

This technique uses automatic molding machines, which allow higher pressures and/or temperatures. The first process step consists of pneumatically pre-compressing the molding compound (i.e. the polymer-coated popcorn) and filling it in the cavity of the mold. Temperature and pressure are used to heat the molding compound. The use of radio wave technology (hν) enables a much faster and efficient molding process. After the popcorn particles have bonded together, the last process step is to remove the molded part from the mold.

Figure 1: Forming presses (Source: DE102018132738A1)

Figure 2: Use of automatic molding machines (Source: DE102020105205.7)

Advantages

- Molded parts made from renewable raw materials

- Production of hydrophobic, very light and flexible moldings

- Very good storability and pourability of the renewable granulate

- Faster and more efficient compression molding process

Applications

- Packaging materials (e.g. cool boxes, protective packaging for electrical appliances);

- automotive parts (e.g. headrests, sun visors, child seat shells, insulating mats);

- insulating materials (e.g. electrical appliances);

- sports equipment (e.g. yoga rolls, bolsters);

- toys (e.g. dice, boards for board games, puzzles);

- Household articles (e.g. spice jars, dishes, baskets, picture frames)

- Faster and more efficient compression molding process

Development Status

Various molded parts (prototypes) were successfully manufactured and tested.

Patent Status

German and international patent applications have been filed (applicant: Georg-August-Universität Göttingen Stiftung Öffentlichen Rechts).

References

DE102018132738A1

WO2020126665A1

DE102020105205A1

WO2021170676A1

Homepage AG Chemistry and process engineering of composite materials:

http://www.uni-goettingen.de/de/72110.html

MDR-YouTube channel:

https://www.youtube.com/watch?v=VtKibTvBVYE

RTL-Nord:

www.rtlnord.de/nachrichten/moebel-aus-popcorn-aus-goettingen.html

HR – Alles Wissen:

https://www.hr-fernsehen.de/sendungen-a-z/alles-wissen/sendungen/alles-wissen,sendung-82690.html

Contact

Dr. Stefan Uhle

Patent Manager Life Science

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel: +49 551 30724 154

Referenz: BioC-2138+2232-SUG