Scalable device for culturing and automatically measuring tissue engineered products

Tissue engineering has made exciting progress over the past two decades, driven by advances in human stem cell biology, tissue engineering and materials science. However, preclinical drug or tox screening still relies on cell culture with poor predictive power or animal testing. Scientists at the University of Göttingen have developed a new device for automated and reliable tissue engineering and drug testing.

Challenge

Bringing a new drug to market can cost billions of dollars and is an enormously time-consuming and expensive process that includes animal testing before human trials - the most costly and difficult part. However, many promising compounds fail when tested in humans. In fact, they may turn out to be ineffective or even harmful. Tissue engineered products (TEPs) have attracted considerable interest as an alternative to cell-based or even animal testing. However, despite the recent advantages of stem cell-based tissue engineering, there is an unmet need for reliable equipment to grow and automatically analyse TEPs for drug or tox screening. Current video-based systems require large data sets to store and analyse. In addition, for contracting tissues such as heart, it would be advantageous to measure both isometric and auxotonic contractions and with different 'preloaded' forces without changing the system.

Our Solution

Scientists at the University of Göttingen have developed a scalable device for cultivating tissue and observing tissue contraction that, despite its streamlined overall design and low cost, allows the properties of engineered tissue constructs (TEPs) to be determined with high precision under a wide range of conditions. This system should reduce the workload and costs associated with this process, as well as the number of animal tests required to test and validate future medicines.

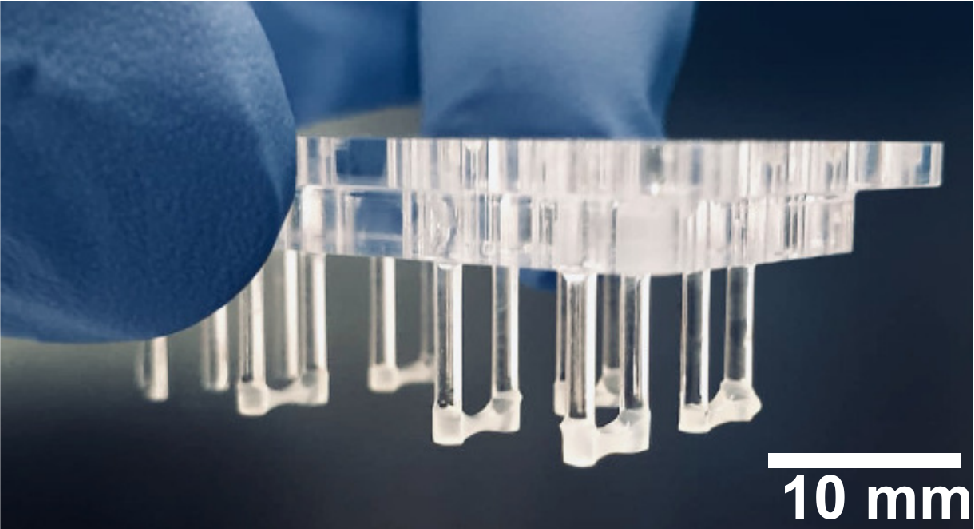

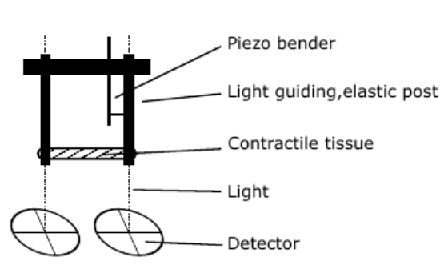

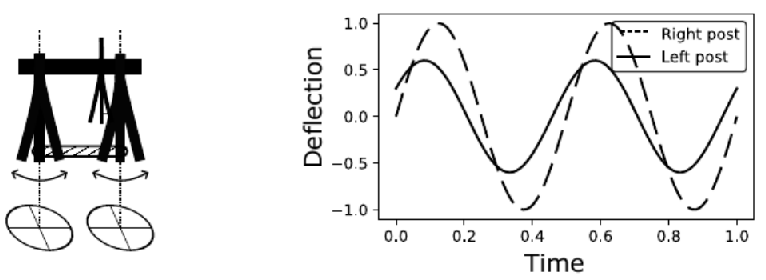

The new device is very versatile and does not rely on monitoring the TEPs with a microscope or video recording system. Instead, it uses a photoelectric system to monitor the position of the two posts on which the tissue construct has grown. The light coupled into the posts and emitted from the lower ends is a pointer that directly indicates the actual position of each lower post and, with a high number of photons, allows the position of each lower post end to be determined with high precision using relatively simple sensors. Nevertheless, the transparent bottom of the culture chamber allows microscopic imaging of the tissue attached to the posts during their contraction with high spatial resolution.

A piezoelectric bending transducer is attached to the elastic posts to change their stiffness and/or position. For example, the bending transducer can be controlled by the light coupled-out at the respective lower post end. By holding the lower end of the post in a specific position with varying forces applied by the tissue attached to the posts, infinite stiffness or rigidity of the respective post is simulated.

A piezoelectric bending transducer is attached to the elastic posts to change their stiffness and/or position. For example, the bending transducer can be controlled by the light coupled-out at the respective lower post end. By holding the lower end of the post in a specific position with varying forces applied by the tissue attached to the posts, infinite stiffness or rigidity of the respective post is simulated (Source: EP23152532.0

Advantage

- Grow and analyse tissue engineered products (TEPs) in a single instrument

- No transfer of TEPs for analysis means less risk of contamination

- Scalable culture platform can be fully automated

- Simple and fully integrated photoelectric detection system

- Versatile with different modes of force generation and detection

- Chamber allows microscopic imaging

Potential measurement modes (Source: EP23152532.0):

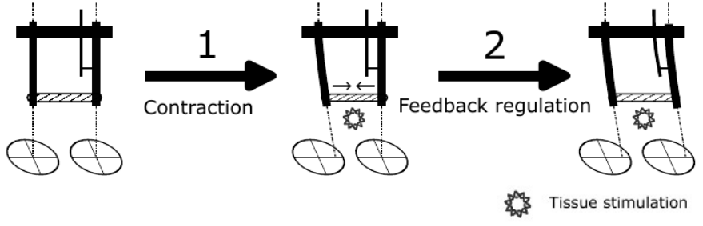

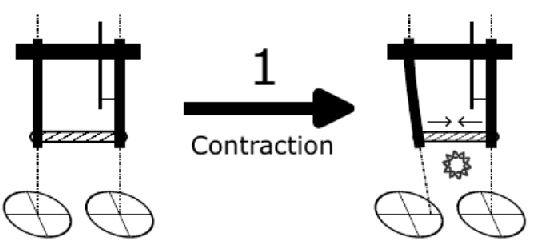

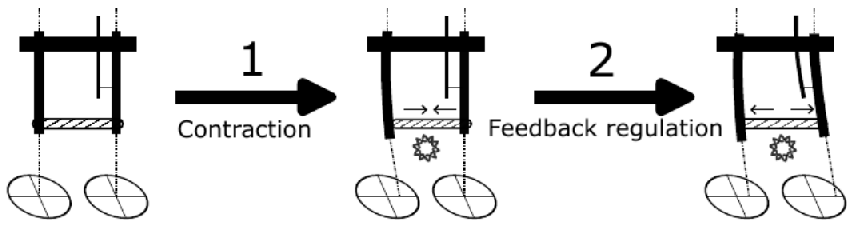

Isometric contraction (tension without length change):

1: Tissue is stimulated and mechanical tension is induced. The tissue contracts, deforms the left post.

2: The length change of the tissue is sensed using both detectors. The piezo bender deforms the right post so that the tissue length stays constant. Effectively the tissue length stays constant while the tissue contracts.

Concentric contraction (tension with length reduction):

1: Tissue is stimulated and mechanical tension is induced. The tissue contracts, deforms the left post. The left post deflection is used to calculate the contractile force.

Eccentric contraction (tension with length increase):

1: Tissue is stimulated and mechanical tension is induced. The tissue contracts, deforms the left post.

2: Knowing the tissue length at all time, the piezo bender is moved such that the tissue length is increasing even tough the tissue is contracting. Effectively the tissue length increases wile the tissue contracts.

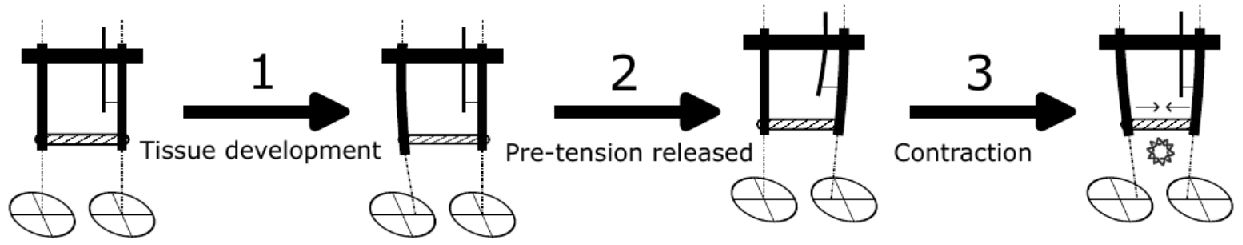

Contraction with reduced/increased pre-tension:

1: During development the tissue generates a mechanical pre-tension which deflects the post.

2: This pre-tension is reduced (increased) by moving the right post to the left (right) until the left post is not deformed. In this position, the tension is released.

3: The tissue gets stimulated and contracts. Using the left post deflection, contractile forces are determined

This approach allows for determining contractile forces dependent on pre-tensions.

Rheology measurement:

Using the piezo bender, sinosoidal forces are applied to the tissue. At the same time, the tissue length in response to the forces is monitored. From these quantities, viscoelastic material properties can be calculated.

Applications

- Preclinical drug or toxicological screening to replace animal testings

- Enhanced laboratory studies – the new system will allow scientists to mimic the mechanical situations that confront various living tissues in serious conditions, such as cardiovascular disease or muscular dystrophies

Development Status

The new device has been successfully tested in lab-scale with stem cell based human heart tissues.

Patent Status

A European patent application has been filed (Applicant: Georg August University of Göttingen public law foundation).

Kontakt

Dr. Stefan Uhle

Patent Manager Life Science

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +49 551 30724 154

Referenz: BioC-2413-UMG