Mould and process for the extrusion of metallic materials

The invention describes moulding tools, which enable the production of extruded metallic parts with predominantly isotropic properties. In addition, a process is proposed, which favours the production of largely isotropic extruded parts with conventional extrusion presses.

Challenge

Extrusion is a compression forming process that can be used to produce tubes, wires, rods and/or (irregularly) shaped profiles. The workpiece is inserted into a feed channel and pressed through a mould with a punch. The material is plastically deformed and an extruded part in the desired shape is created. The extruded parts produced in this way (made of, for example, magnesium materials) often show strongly anisotropic (direction-dependent) mechanical properties, such as a tensile-compressive and/or bending anisotropy. Hence, their application as structural components is severely limited. In order to achieve an improved isotropic (direction-independent) mechanical behaviour of the extruded parts, alloy components/elements can be added to the extruded material. However, the extrudability is degraded due to strongly increasing pressing forces. Multiple extrusion of the same profile with an angled feed channel also allows the creation of workpieces/parts with an increased isotropy. However, with the currently available presses this is not easily feasible.

Our Solution

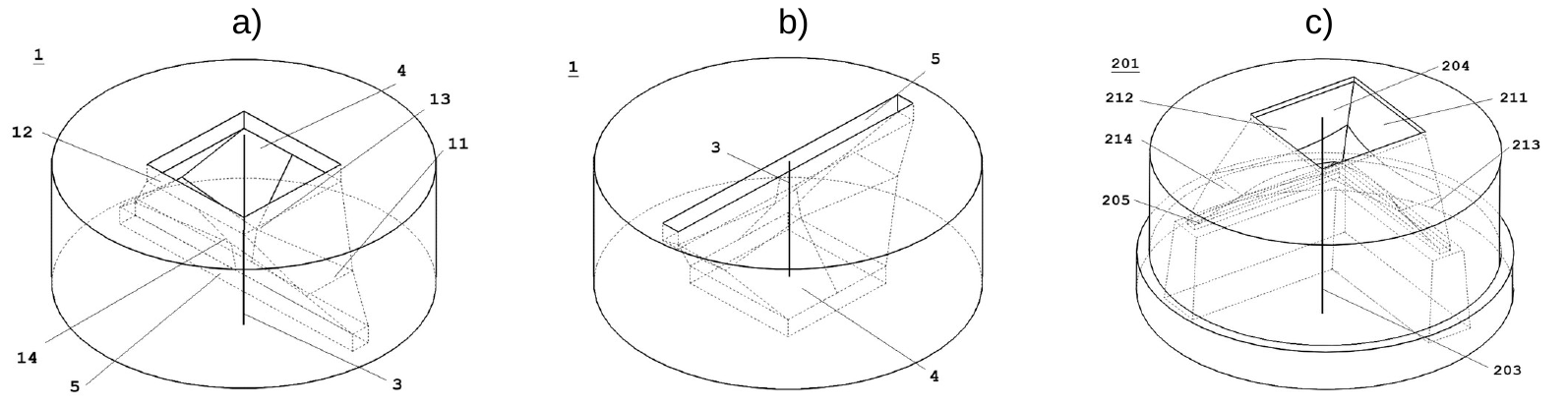

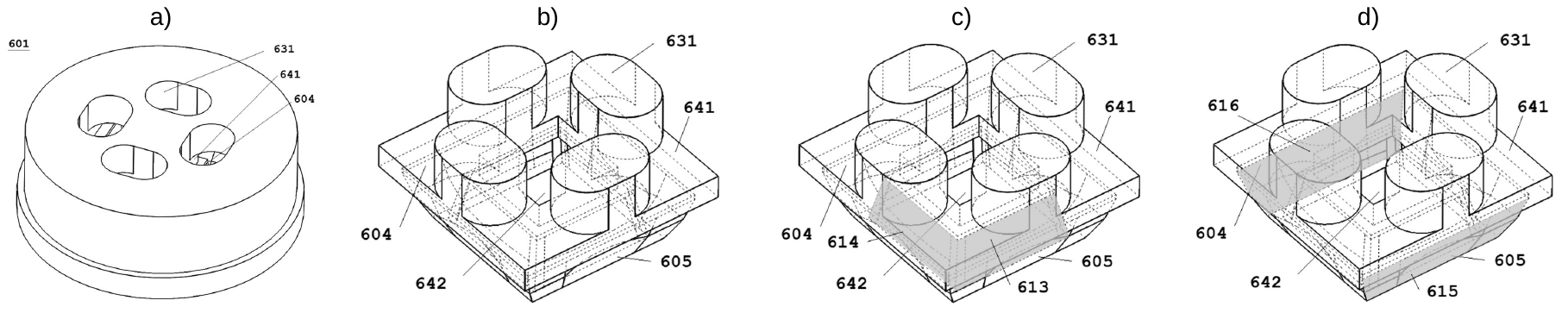

Scientists from the Leuphana University of Lüneburg and Helmholtz-Center Geesthacht have developed moulding tools, which overcome the aforementioned limitations and enable the production of metallic extruded parts with isotropic properties. According to the present invention, the forming process of the metallic material takes place within the extrusion die of the moulding tools. In contrast to conventional extrusion presses, the entire material flow in the inner and outer laminar layers is moved vertically and transversely to the extrusion direction. According to the invention, a mould with a die with at least one die channel wall is used, which is curved into the die channel. The sewer cross-sectional surfaces defined by the die channel walls remain essentially constant in size. Fig. 1 and Fig. 2 show examples of possible embodiments of extrusion matrices for the production of isotropic, metallic workpieces/parts, according to the present invention.

Fig. 1: Extrusion moulding dies for the production of a) and b) sheet plate and c) L-type and metallic profiles with isotropic properties (adaptation after patent application).

Fig. 1: Extrusion moulding dies for the production of a) and b) sheet plate and c) L-type and metallic profiles with isotropic properties (adaptation after patent application).

Fig. 2: Extrusion moulding die for the production of hollow metallic parts with isotropic properties. The details of the same moulding tool are shown in a-d). The gray shaded areas highlight some mould channel walls (adaptation after patent application).

Fig. 2: Extrusion moulding die for the production of hollow metallic parts with isotropic properties. The details of the same moulding tool are shown in a-d). The gray shaded areas highlight some mould channel walls (adaptation after patent application).

Advantages

- Production of extruded metallic parts with isotropic mechanical properties

- Flexible adaptation to the manufacturing of metallic sheet plate, L-type and hollow profiles available

- Adaptation of the process to conventional presses possible

- Extrusion moulding dies can be easily fabricated by e.g. 3D metal printing

Applications

- Production of parts/components made of magnesium, aluminium as well as magnesium and aluminium alloys with isotropic properties

- Exploitation of the technology in the metal and automotive industry

Development Status

The moulding tools have been successfully developed and tested. The production process of metallic parts with the moulding tools have been approved.

Patent Status

German patent application granted: DE102020128163

International patent application: WO2022090135A1

Patent holder: Leuphana University Lüneburg Foundation under public law

Contact

Dr. Mirza Mackovic

Patent Manager Technology

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Phone: +49 551 30724 153

Reference: CPA-2252-ULue