Process technology for a rapid production of sustainable and functional composite structures

A process technology is suggested, which enables an efficient manufacturing of functional composite structures with a plant-based core material and relatively short processing times.

Challenge

Sandwich core structures are often composed of two top layers from glass, natural, aramid or carbon fibers and a relatively soft core, which can be based on polymer materials. Such structures can exhibit superior bending and torsion properties in combination with a light weight potential. Available production technologies often involve vacuum conditions and relatively high temperatures, which can have a negative impact on processability, throughput and costs. The known pre-preg technology enables the production of composites made from pre-impregnated fibers and a partially cured polymer matrix. However, the resulting composites structures will mostly require an autoclave or oven for curing. Consequently, longer cycle times and enormous energy efforts can increase the final product costs. The resin injection technique is another possibility to produce composite structures. Thereby, the required tools need to be hermetically sealed and structured with integrated resin flow channels, in order to be used under vacuum conditions and for dedicated resin impregnation. This can lead to a cost- and time-intensive processing.

Our Solution

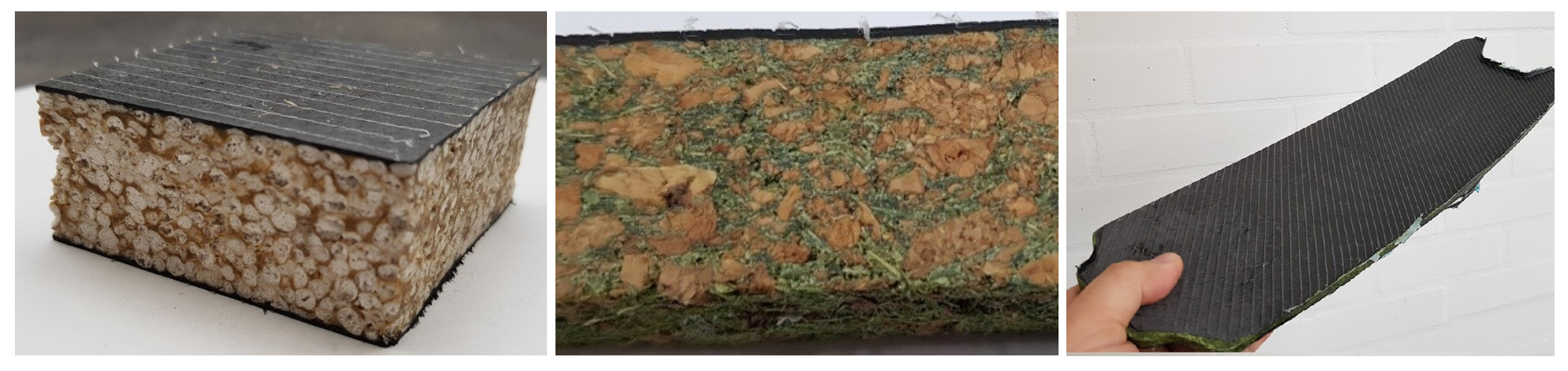

A process technology for an efficient production of sustainable sandwich core structures, which are composed of a fiber bulk material positioned between two top layers, is suggested. The top layers can be textile, knitted fabrics, interlaced yarns, fleece or non-woven fabrics, which contain a specific content of technical fibers composed of carbon, glass or aramid. According to the invention, the matrix of the core structure can be a polymer material, which is specifically mixed with natural fibers. The natural fibers have specific lengths ranging from the µm- to the mm-range. The final sandwich structure (top layers + fiber bulk material) is fabricated by hot pressing at relatively low temperatures. Hot pressing allows the fabrication of either flat or complexly bent 3D composite structures. In some embodiments it can be intended to insert inlay materials between the top layers. By choosing the top layer material and controlling the compactness of the core material, the composite structures can be engineered for various applications. Fig. 1: Exemplary composite structures and functional elements fabricated according to the present invention and patent applications (source: Dr. Steuernagel and Mr. Kusmin, Clausthal University of Technology).

Fig. 1: Exemplary composite structures and functional elements fabricated according to the present invention and patent applications (source: Dr. Steuernagel and Mr. Kusmin, Clausthal University of Technology).

Advantages

- Form stable, weatherproof and durable composite structures with good mechanical properties

- Structural elements with flexible shape and geometry

- No structural degradation by microorganisms

- Short processing times

- Bulk fiber material contains natural, sustainable and renewable resources

- Functionalization with structural elements possible

- No pre-pregs or vacuum needed

- Cost-, resource- and energy-efficient process technology

Applications

- Automotive sector

- Construction industry

- Functional electronics

- Sports equipment

- Packaging industry

- Furniture and toy industry

Development Status

The technology has been successfully developed on laboratory scale. Prototypes are available. Process scaling aimed.

Patent Status

German patent application: DE102023104439.7

International patent application: PCT/EP2023/085541

Patent applicant: Clausthal University of Technology

Contact

Dr. Mirza Mackovic

Patent Manager Technology

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +49 551 30724 153

Reference: CPA-2378-T286